Haulpak Komatsu 930E-4 is one large dump truck. Judging from its name, we can determine the specifications of these trucks dump. Haulpak is a brand of that unit in the manufacturer Komatsu. 930 is the capacity of the units of £ 930,000 or 422 Tons.

SPECIFICATIONS KOMATSU HAULPAK 930E-4

ENGINE

Make and model . . . . . . . . . . . . . Komatsu SSDA16V160*

Fuel . . . . . . . . . . . . . . . . . .Diesel

Number of cylinders . . . . . . . . . . .16

Operating cycle . . . . . . . . . . . . .4 cycle

Rated brake power** . . . . . . . . . . 2014 kW 2,700 HP @ 1900 rpm

Flywheel power*** . . . . . . . . . . . 1902 kW 2,550 HP @ 1900 rpm

Weight (wet) . . . . . . . . . . . . . . 9608 kg 21,182 lb

* Tier 2 emissions compliant. Tier 1 emissions engine is optional outside of North America.

** Rated brake power is the output of the engine as installed in this machine, at governed rpm and with engine manufacturer’s approved fuel setting. Accessory losses included are water pump, fuel pump and oil pump.

*** Flywheel power is the rated power at the engine flywheel minus the average accessory losses. Accessories include fan and charging alternator. Rating(s) represent net engine performance in accordance with SAE J1349 conditions.

ELECTRIC DRIVE

AC/DC CURRENT

Alternator . . . . . . . . . . . . . . . GTA-41

Dual impeller in-line blower . . . . . .340 m3/min 12,000 cfm

Control . . . . . . . . . . . . . . . . .AC Torque Control System

Motorized wheels* . . . . . . . . . . . GDY106 Induction Traction Motors

Ratio** . . . . . . . . . . . . . . . . 32.62:1

Speed (maximum) . . . . . . . . . . . . 64.5 km/h 40 mph

* Wheel motor application depends upon gross vehicle weight, haul road grade, haul road length, rolling resistance and other parameters. Komatsu and G.E. must analyze each job condition to assure proper application.

** Optional ratios available.

TIRES AND RIMS

Rock service, tubeless, radial tires

Standard tire*. . . . . . . . . . . . . 53/80 R63

Taper lock, five (5) piece rim

914 mm x 1600 mm x 127 mm 36'' x 63'' x 5.0'' rim assembly.

Rims rated at 758 kPa 110 psi cold inflation pressure.

Typical tire weight . . . . . . . . .26127 kg 57,600 lb

* Tires should meet application requirements for tkph/tmph, tread, compound, inflation pressure, ply rating or equivalent, etc.

BODY

All-welded steel flat floor body with horizontal bolsters and full canopy. Eyebrow, rear wheel rock ejectors, body up sling and rubber mounts on frame are standard. Pivot exhaust heating optional.

Floor sheet . . . . . . . . . . . . 16 mm 0.63'' 1379 mPa 200,000 psi tensile strength steel (two-piece)

Front sheet . . . . . . . . . . . . .9 mm 0.35'' 1379 mPa 200,000 psi tensile strength steel

Side sheet . . . . . . . . . . 8 mm 0.31'' 1379 mPa 200,000 psi tensile strength steel

Canopy sheet . . . . . . . .5 mm 0.19'' 690 mPa 100,000 psi

Struck . . . . . . . . . . . . . . . 171 m3 224 yd3

Standard SAE heaped 2:1 . . . . . . .211 m3 276 yd3

Standard Komatsu body weight . . . 30362 kg 66,936 lb

*Komatsu must approve all bodies through a Body Application Worksheet

CAB

Advanced Operator Environment with integral 4-post ROPS/FOPS structure Level 2, adjustable air suspension seat w/lumbar support and arm rests, full-size passenger seat, maximum R-value insulation, tilt and telescoping steering wheel, electric windshield wipers w/washer, tinted safety glass, power windows, Komatsu Payload Weighing System, 55,000 Btu/hr heater and defroster, 21,600 BTU/hr air conditioning (HFC - 134A refrigerant).

FRAME

Advanced technology, full butt-welded box sectional ladder-type frame with integral ROPS supports,integral front bumper, rear tubular cross members, steel castings at all critical stress transition zones, rugged continuous horsecollar.

Plate material . . . . . . . . . . 482.6 mPa 70,000 psi tensile strength steel

Casting material . . . . . . . . . 620.5 mPa 90,000 psi tensile strength steel

Rail width . . . . . . . . . . . .305 mm 12''

Rail depth (minimum) . . . . . . . 864 mm 34''

Top and bottom plate thickness . .45 mm 1.77''

Side plate thickness . . . . . . .25 mm 0.98''

Drive axle mounting . . . . . . . Pin and spherical bushing

Drive axle alignment . . . . . . .Swing link between frame and axle

BRAKING SYSTEM

Service brakes: oil-cooled, hydraulic-actuated, multiple disc brakes at each wheel. Traction system wheel slip/slide control.

Max. service apply pressure . . . .17237 kPa 2500 psi

Total friction area per brake . . .97025 cm2 15,038 in2

Emergency brakes . . . . . . . . .Automatically applied prior to hydraulic system pressure dropping below level required to meet secondary stopping requirements.

Wheel brake locks . . . . . . . . .Switch activated

Parking brakes . . . . . . . . . . Multiple disc, spring-applied, to hydraulic system pressure dropping below level required to meet secondary stopping requirements.

Wheel brake locks . . . . . . . . .Switch activated

Parking brakes . . . . . . . . . . Multiple disc, spring-applied,

hydraulically-released, dry brakes on inboard end

hydraulically-released, dry brakes on inboard end

±15% grade at maximum gross vehicle weight.

Electric dynamic retarder . . . . .Max 4026 kW 5400 hp Continuous 2460 kW 3300 hp Continuously rated high-density blown grids w/retard capacity at low speeds and retard in reverse propulsion.

SUSPENSION

Variable rate hydro-pneumatic with integral rebound control

Max. front stroke . . . . . . . . . .328 mm 12.92''

Max. rear stroke . . . . . . . . . . 239 mm 9.40''

Max. rear axle oscillation . . . . . ±6.5°

COOLING SYSTEM

L&M radiator assembly, split-flow, with deaerator-type top tank.

Radiator frontal area . . . . . . . .7.02 m 75.5 ft

SERVICE CAPACITIES Cooling system . . . . . . . . .594 L . . . .157 U.S. gal

Crankcase* . . . . . . . . . . . . .280 L . . . . .74 U.S. gal

Hydraulic system . . . . . . . . . 1325 L . . . .350 U.S. gal

Motor gear box (each) . . . . . . .95 L . . . . .25 U.S. gal

Fuel . . . . . . . . . . . . . . . . 4542 L . . .1200 U.S. gal

* Includes lube oil filters

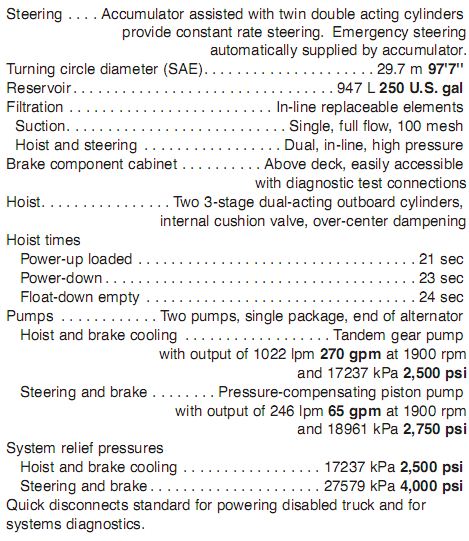

Hydraulic System

Electric System

Weight Distribution

Source : KOMATSU HAULPAK

Posted in:

Posted in:

0 comments:

Post a Comment