KOMATSU HD 1500-7 Productivity and Economy Features

● High performance Komatsu SDA12V160 engine Net horsepower 1048kW 1,406HP

● Komatsu 7 speed, electronically controlled automatic powershift transmission

● 4-wheel oil-cooled, multiple-disc retarder

● Automatic Retard Speed Control (ARSC) standard

KOMATSU HD 1500-7 Reliability Features

● Flat face-to-face O-ring seals

● Sealed DT connectors

● Fully hydraulic brakes - no air system

● High performance Komatsu SDA12V160 engine Net horsepower 1048kW 1,406HP

● Komatsu 7 speed, electronically controlled automatic powershift transmission

● 4-wheel oil-cooled, multiple-disc retarder

● Automatic Retard Speed Control (ARSC) standard

KOMATSU HD 1500-7 Reliability Features

● Flat face-to-face O-ring seals

● Sealed DT connectors

● Fully hydraulic brakes - no air system

HD 1500-7 ENGINE SPECIFICATION

Model. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Komatsu SDA12V160

Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Water-cooled, 4-cycle

Aspiration. . . . . . . . . . . . . . . . . . . . . . . . . Turbo-charged, after-cooled

Number of cylinders. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Bore x Stroke. . . . . . . . . . . . . . . . . 159 mmx 190 mm 6.26"x 7.48"

Piston displacement. . . . . . . . . . . . . . . . . . . . . . . . . . 45 ltr 2,746 in3 Horsepower

SAE J1995. . . . . . . . . . . . . . . . . . . . . . . Gross 1109 kW 1,487 HP

ISO 9249 / SAE J1349. . . . . . . . . . . . . . . Net 1048 kW 1,406 HP

Rated rpm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1,900 rpm

Fan drive type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Mechanical

Maximum torque. . . . . . . . . . . . . . . . . . . . . . . . 697 kg•m 5,041 lb ft

Fuel system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Direct injection

Governor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Electronic control Lubrication system

Method. . . . . . . . . . . . . . . . . . . . . . . . Gear pump, force-lubrication

Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Full-flow type

Air cleaner. . . . . . . . . . . . . . . . . . Dry type with double elements and pre-cleaned, with dust indicator

HD 1500 TRANSMISSION

Torque converter. . . . . . . . . . . . . . . . . . 3-elements, 1-stage, 2-phase

Transmission. . . . . . . . . . . . . . . . Full-automatic, planetary-shaft type

Speed range. . . . . . . . . . . . . . . . . . . 7 speeds forward and 1 reverse

Lockup clutch. . . . . . . . . . . . . . . . . . . . . . . . . Wet, multiple-disc clutch

Forward. . . . . . . . . . . . . . . . Torque converter drive 1st and 2nd gear with direct drive lock-up in 1st through 7th

Reverse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Torque converter drive

Shift control. . . . . . . . . . . . . . . . Electronic shift control with automatic clutch modulation in all gears

Maximum travel speed . . . . . . . . . . . . . . . . . . . . . .58 km/h 36 mph

HD 1500 AXLES

Rear axles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Full-floating

Final drive type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Planetary gear

Ratios:

Differential. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.647

Planetary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.235

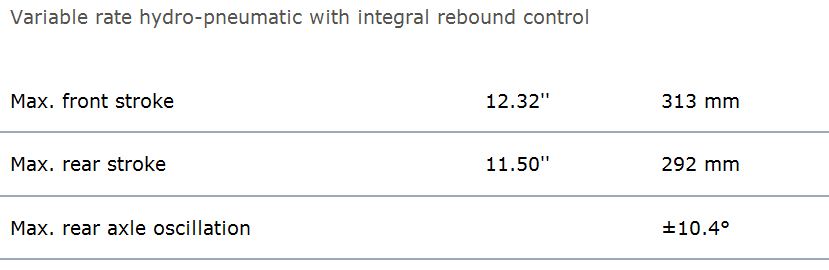

HD 1500 SUSPENSION SYSTEM

Variable rate, hydropneumatic with integral rebound control.

Maximum front stroke. . . . . . . . . . . . . . . . . . . . . . . . . 375 mm 14.76"

Maximum rear stroke. . . . . . . . . . . . . . . . . . . . . . . . . . . . 106 mm 4.17"

Rear axle oscillation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +/- 9.2°

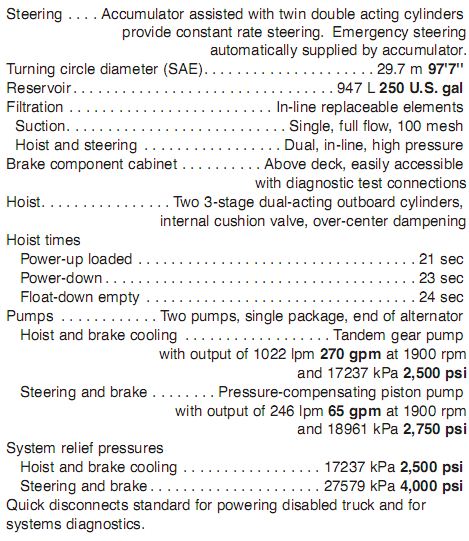

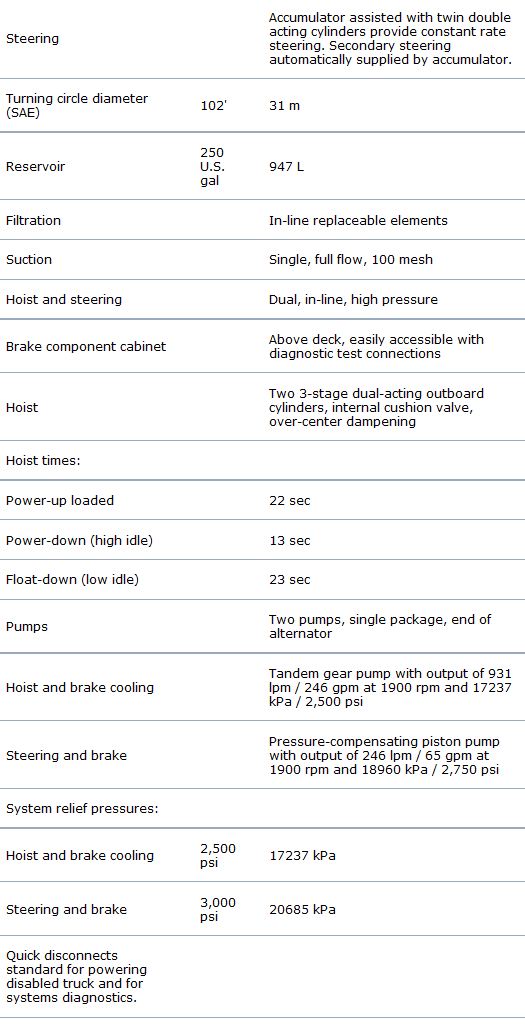

HD 1500 STEERING SYSTEM

Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fully hydraulic power steering with two double-acting cylinders,

Supplementary steering. . . . . . . . . . . . . . . . . . . . . . Accumulator assist

Minimum turning radius. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12.2 m 40'

Steering angle (left or right). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41°

HD 1500 CAB

Integral 4-post ROPS/FOPS cab structure (meets SAEJ 1040 Apr 88)

HD 1500 MAIN FRAME

Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Box-sectioned structure Integral front bumper

HD 1500 BRAKES

Brakes meet ISO 3450 standard.

Service brakes:

Front. . . . . . . . . . Fully hydraulic control, oil-cooled multiple-disc type

Rear. . . . . . . . . . Fully hydraulic control, oil-cooled multiple-disc type

Parking brake . . . .Spring applied, oil-released, 3 caliper dry disc mounted on input yoke to differential

Retarder. . . Oil-cooled, multiple-disc front and rear brakes act as retarder.

Secondary brake. . . . . . . . . . . . . . . . . . Manual - push button operated.

Automatically applied prior to hydraulic system pressure dropping below established level.

Braking surface. . . . . . . . . . . . . . . . . . . . . . . . . . 159148 cm2 24,668 in2

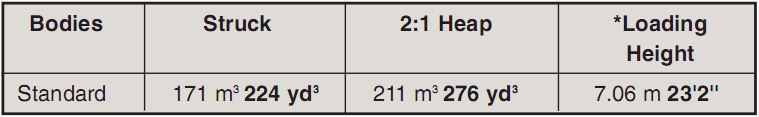

HD 1500 BODY

Capacity:

Struck. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54 m3 71 yd3

Heaped (2:1, SAE). . . . . . . . . . . . . . . . . . . . . . . . . . 78 m3 102 yd3

Nominal payload. . . . . . . . . . . . . . 144.1 metric tons 158.9 U.S.tons

Material. . . . . . . . . . . 400 Brinell hardness high tensile strength steel (front, sides, and bottom)

Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Flat floor configuration

Material thickness:

Bottom. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 mm 0.75"

Front. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 mm 0.47"

Sides. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 mm 0.35"

Target area (inside length x width). . . . . . . 7670 mm x 5705 mm 25'2"x 18'9"

Dumping angle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45°

Height at full dump. . . . . . . . . . . . . . . . . . . . . . . . . . 11440 mm 37'6"

Heating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Exhaust heating

HD 1500 HYDRAULIC SYSTEM

Hoist cylinder. . . . . . . . . . . . . . . . . . . . . . Two, 3-stage telescopic type

Relief pressure. . . . . . . . . . . . . . . . 19.0 MPa 193.4 kg/cm2 2,750 psi

Hoist time

Raise. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 sec

Lower. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 sec

HD 1500 WEIGHT (APPROXIMATE)

Empty weight. . . . . . . . . . . . . . . . . . . . . . . . . 105300 kg 232,144 lb

Max.gross vehicle weight. . . . . . . . . . . . . . . . 249478 kg 550,000 lb

Not to exceed max.gross vehicle weight, including options, fuel and payload.Empty weight is with 100% fuel and operator.

Weight distribution:

Empty:Front axle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48.6%

Rear axle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51.4%

Loaded:Front axle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32.8%

Rear axle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67.2%

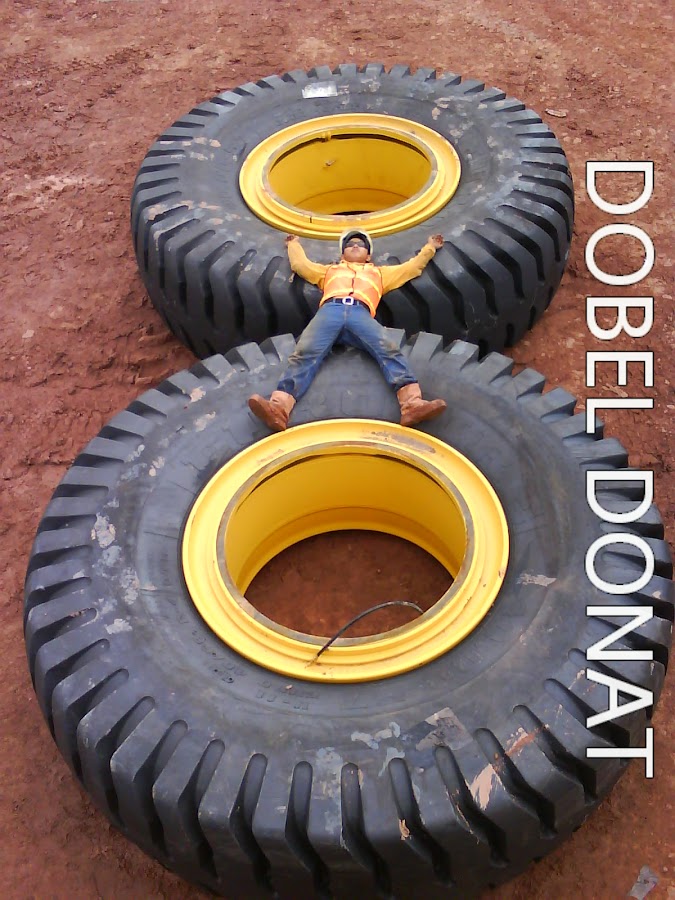

HD 1500 TIRES

Standard tire. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33.00 R51

HD 1500 SERVICE REFILL CAPACITIES

Fuel tank . . . . . . . . . . . . . . . . . . . . . . . . . . . .2120 ltr. 560 U.S.Gal

Engine oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . .193 ltr. 51 U.S.Gal

Hydraulic system . . . . . . . . . . . . . . . . . . . . . . .900 ltr. 238 U.S.Gal

Differential . . . . . . . . . . . . . . . . . . . . . . . . . . . .297 ltr. 78 U.S.Gal

Final drives (total) . . . . . . . . . . . . . . . . . . . . . .240 ltr. 63.5 U.S.Gal

Transmission . . . . . . . . . . . . . . . . . . . . . . . . . .153 ltr. 40.5 U.S.Gal

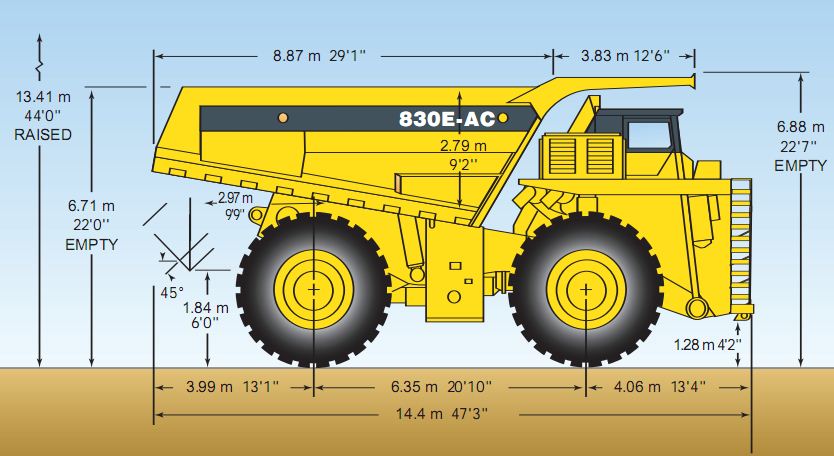

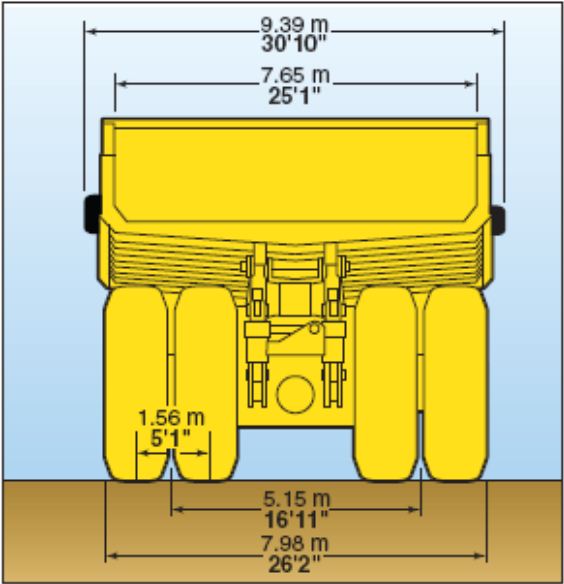

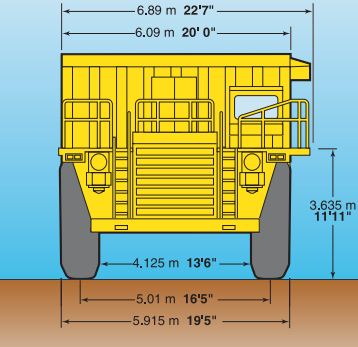

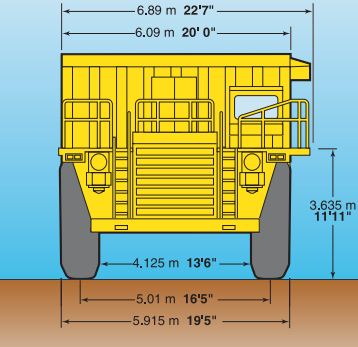

HD 1500 DIMENSIONS

HD 1500 STANDARD EQUIPMENT

POWERTRAIN

● Air cleaner (2);battery disconnect; engine electronic control;engine electronic monitor;engine overspeed protection;engine pre-lube system; ground level shutdown;variable speed engine fan (electronic-over-hydraulic)

● Powertrain Management (these items located in the cab):

–transmission controller

–retard controller

–monitor display

–data download port

● Seven-speed automatic transmission:

–electronic control

–body-up reverse interlock

–body-up shift inhibitor

–downshift/reverse shift inhibitor

–neutral start switch

–transmission belly guard

● Torque converter (electronic lockup control)

CAB

● Air conditioning (R134A)

● Electric windows (both doors)

● Glass, tinted

● Heater/defroster

● Instrumentation (gauge and monitor):

–speedometer

–tachometer

–engine coolant temperature

–brake oil temperature

–fuel lever

–shift indicator

–hourmeter

–odometer

–torque converter temperature

–warning lights

● Insulated and sound-suppressed

● Radio, AM/FM/Cassette

● Seat, air suspension (driver)

● Seat, passenger

● Seat belts 78 mm 3" retractable

● Steering wheel, tilt and telescopic

● Sun visor

● Windshield washer and wiper

LIGHTING

● Back-up light, rear (1)

● Back-up lights, deck-mounted (2)

● Clearance lights, front

● Engine service lights (2)

● Headlights, halogen (8)

● Hi-low beam selector

● Instrument panel lights

● Ladder lights, driver side

● Retarder lights (2)

● Stop and tail lights LED

● Turn signals LED GENERAL

● Back-up warning alarm

● Body up cable

● Cab guard (on canopy)

● Drive line protector (front and rear)

● Engine fan and pulley guards

● Exhaust pipe blanket

● Ground level engine shutdown

● Handrails

● Heat shield behind engine

● Horn, electric (2)

● Ladder, deck-to-transmission

● Ladders, right and left (front)

● Mirrors, right and left

● Mud flaps

● Parking brake (3 caliper, spring-applied)

● Reverse hoist interlock

● Rock ejectors

● ROPS cab (integral 4-post)

● Secondary brake system, automatic and manual

● Skid-resistant walkway on deck

● Supplementary steering system, automatic

● Windshield, laminated safety glass OTHER

● Auto-Retard Speed Control (ARSC)

● Automatic Spin Regulator (ASR)

● Automatic lubrication system

● Body mounting group

● Fast fill fuel system (Wiggins) right-hand side of the machine

● Integrated Komatsu Payload Meter

● Operation, parts, and maintenance manuals (1 set)

● Rims (6), 24 x 51 (for 33 x 51 and 33R51 tires)

● Tow hooks, front

● Tow pin, rear

● Vehicle health monitoring system (VHMS)

HD 1500 OPTIONAL EQUIPMENT

(Optional equipment may change operating weight.)

Weights listed are approximate change from operating weight.

Hub odometer, miles or kilometers . . . . . . . . . . . . . . . .2 kg 5 lb

Disabled truck quick connects . . . . . . . . . . . . . . . . .13.5 kg 29.8 lb

Kim Hot Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 kg 35 lb

Fast fill fuel, Wiggins left-hand side . . . . . . . . . . . . . . .2 kg 5 lb

Fast oil change, Wiggins (engine) . . . . . . . . . . . . . . . . .7 kg 15 lb

Service center, Wiggins left-hand side . . . . . . . . . . . .36 kg 80 lb

Muffler, deck-mounted . . . . . . . . . . . . . . . . . . . . . . . .50 kg 110 lb

Fire extinguisher . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14 kg 30 lb

Body liners

–19 mm 0.75" floor, 9 mm 0.35" side, front and rear half of canopy (400 Brinell Steel) . . . . . . .8320 kg 18,340 lb

Model. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Komatsu SDA12V160

Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Water-cooled, 4-cycle

Aspiration. . . . . . . . . . . . . . . . . . . . . . . . . Turbo-charged, after-cooled

Number of cylinders. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Bore x Stroke. . . . . . . . . . . . . . . . . 159 mmx 190 mm 6.26"x 7.48"

Piston displacement. . . . . . . . . . . . . . . . . . . . . . . . . . 45 ltr 2,746 in3 Horsepower

SAE J1995. . . . . . . . . . . . . . . . . . . . . . . Gross 1109 kW 1,487 HP

ISO 9249 / SAE J1349. . . . . . . . . . . . . . . Net 1048 kW 1,406 HP

Rated rpm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1,900 rpm

Fan drive type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Mechanical

Maximum torque. . . . . . . . . . . . . . . . . . . . . . . . 697 kg•m 5,041 lb ft

Fuel system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Direct injection

Governor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Electronic control Lubrication system

Method. . . . . . . . . . . . . . . . . . . . . . . . Gear pump, force-lubrication

Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Full-flow type

Air cleaner. . . . . . . . . . . . . . . . . . Dry type with double elements and pre-cleaned, with dust indicator

HD 1500 TRANSMISSION

Torque converter. . . . . . . . . . . . . . . . . . 3-elements, 1-stage, 2-phase

Transmission. . . . . . . . . . . . . . . . Full-automatic, planetary-shaft type

Speed range. . . . . . . . . . . . . . . . . . . 7 speeds forward and 1 reverse

Lockup clutch. . . . . . . . . . . . . . . . . . . . . . . . . Wet, multiple-disc clutch

Forward. . . . . . . . . . . . . . . . Torque converter drive 1st and 2nd gear with direct drive lock-up in 1st through 7th

Reverse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Torque converter drive

Shift control. . . . . . . . . . . . . . . . Electronic shift control with automatic clutch modulation in all gears

Maximum travel speed . . . . . . . . . . . . . . . . . . . . . .58 km/h 36 mph

HD 1500 AXLES

Rear axles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Full-floating

Final drive type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Planetary gear

Ratios:

Differential. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.647

Planetary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.235

HD 1500 SUSPENSION SYSTEM

Variable rate, hydropneumatic with integral rebound control.

Maximum front stroke. . . . . . . . . . . . . . . . . . . . . . . . . 375 mm 14.76"

Maximum rear stroke. . . . . . . . . . . . . . . . . . . . . . . . . . . . 106 mm 4.17"

Rear axle oscillation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +/- 9.2°

HD 1500 STEERING SYSTEM

Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fully hydraulic power steering with two double-acting cylinders,

Supplementary steering. . . . . . . . . . . . . . . . . . . . . . Accumulator assist

Minimum turning radius. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12.2 m 40'

Steering angle (left or right). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41°

HD 1500 CAB

Integral 4-post ROPS/FOPS cab structure (meets SAEJ 1040 Apr 88)

HD 1500 MAIN FRAME

Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Box-sectioned structure Integral front bumper

HD 1500 BRAKES

Brakes meet ISO 3450 standard.

Service brakes:

Front. . . . . . . . . . Fully hydraulic control, oil-cooled multiple-disc type

Rear. . . . . . . . . . Fully hydraulic control, oil-cooled multiple-disc type

Parking brake . . . .Spring applied, oil-released, 3 caliper dry disc mounted on input yoke to differential

Retarder. . . Oil-cooled, multiple-disc front and rear brakes act as retarder.

Secondary brake. . . . . . . . . . . . . . . . . . Manual - push button operated.

Automatically applied prior to hydraulic system pressure dropping below established level.

Braking surface. . . . . . . . . . . . . . . . . . . . . . . . . . 159148 cm2 24,668 in2

HD 1500 BODY

Capacity:

Struck. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54 m3 71 yd3

Heaped (2:1, SAE). . . . . . . . . . . . . . . . . . . . . . . . . . 78 m3 102 yd3

Nominal payload. . . . . . . . . . . . . . 144.1 metric tons 158.9 U.S.tons

Material. . . . . . . . . . . 400 Brinell hardness high tensile strength steel (front, sides, and bottom)

Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Flat floor configuration

Material thickness:

Bottom. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 mm 0.75"

Front. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 mm 0.47"

Sides. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 mm 0.35"

Target area (inside length x width). . . . . . . 7670 mm x 5705 mm 25'2"x 18'9"

Dumping angle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45°

Height at full dump. . . . . . . . . . . . . . . . . . . . . . . . . . 11440 mm 37'6"

Heating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Exhaust heating

HD 1500 HYDRAULIC SYSTEM

Hoist cylinder. . . . . . . . . . . . . . . . . . . . . . Two, 3-stage telescopic type

Relief pressure. . . . . . . . . . . . . . . . 19.0 MPa 193.4 kg/cm2 2,750 psi

Hoist time

Raise. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 sec

Lower. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 sec

HD 1500 WEIGHT (APPROXIMATE)

Empty weight. . . . . . . . . . . . . . . . . . . . . . . . . 105300 kg 232,144 lb

Max.gross vehicle weight. . . . . . . . . . . . . . . . 249478 kg 550,000 lb

Not to exceed max.gross vehicle weight, including options, fuel and payload.Empty weight is with 100% fuel and operator.

Weight distribution:

Empty:Front axle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48.6%

Rear axle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51.4%

Loaded:Front axle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32.8%

Rear axle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67.2%

HD 1500 TIRES

Standard tire. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33.00 R51

HD 1500 SERVICE REFILL CAPACITIES

Fuel tank . . . . . . . . . . . . . . . . . . . . . . . . . . . .2120 ltr. 560 U.S.Gal

Engine oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . .193 ltr. 51 U.S.Gal

Hydraulic system . . . . . . . . . . . . . . . . . . . . . . .900 ltr. 238 U.S.Gal

Differential . . . . . . . . . . . . . . . . . . . . . . . . . . . .297 ltr. 78 U.S.Gal

Final drives (total) . . . . . . . . . . . . . . . . . . . . . .240 ltr. 63.5 U.S.Gal

Transmission . . . . . . . . . . . . . . . . . . . . . . . . . .153 ltr. 40.5 U.S.Gal

HD 1500 DIMENSIONS

HD 1500 STANDARD EQUIPMENT

POWERTRAIN

● Air cleaner (2);battery disconnect; engine electronic control;engine electronic monitor;engine overspeed protection;engine pre-lube system; ground level shutdown;variable speed engine fan (electronic-over-hydraulic)

● Powertrain Management (these items located in the cab):

–transmission controller

–retard controller

–monitor display

–data download port

● Seven-speed automatic transmission:

–electronic control

–body-up reverse interlock

–body-up shift inhibitor

–downshift/reverse shift inhibitor

–neutral start switch

–transmission belly guard

● Torque converter (electronic lockup control)

CAB

● Air conditioning (R134A)

● Electric windows (both doors)

● Glass, tinted

● Heater/defroster

● Instrumentation (gauge and monitor):

–speedometer

–tachometer

–engine coolant temperature

–brake oil temperature

–fuel lever

–shift indicator

–hourmeter

–odometer

–torque converter temperature

–warning lights

● Insulated and sound-suppressed

● Radio, AM/FM/Cassette

● Seat, air suspension (driver)

● Seat, passenger

● Seat belts 78 mm 3" retractable

● Steering wheel, tilt and telescopic

● Sun visor

● Windshield washer and wiper

LIGHTING

● Back-up light, rear (1)

● Back-up lights, deck-mounted (2)

● Clearance lights, front

● Engine service lights (2)

● Headlights, halogen (8)

● Hi-low beam selector

● Instrument panel lights

● Ladder lights, driver side

● Retarder lights (2)

● Stop and tail lights LED

● Turn signals LED GENERAL

● Back-up warning alarm

● Body up cable

● Cab guard (on canopy)

● Drive line protector (front and rear)

● Engine fan and pulley guards

● Exhaust pipe blanket

● Ground level engine shutdown

● Handrails

● Heat shield behind engine

● Horn, electric (2)

● Ladder, deck-to-transmission

● Ladders, right and left (front)

● Mirrors, right and left

● Mud flaps

● Parking brake (3 caliper, spring-applied)

● Reverse hoist interlock

● Rock ejectors

● ROPS cab (integral 4-post)

● Secondary brake system, automatic and manual

● Skid-resistant walkway on deck

● Supplementary steering system, automatic

● Windshield, laminated safety glass OTHER

● Auto-Retard Speed Control (ARSC)

● Automatic Spin Regulator (ASR)

● Automatic lubrication system

● Body mounting group

● Fast fill fuel system (Wiggins) right-hand side of the machine

● Integrated Komatsu Payload Meter

● Operation, parts, and maintenance manuals (1 set)

● Rims (6), 24 x 51 (for 33 x 51 and 33R51 tires)

● Tow hooks, front

● Tow pin, rear

● Vehicle health monitoring system (VHMS)

HD 1500 OPTIONAL EQUIPMENT

(Optional equipment may change operating weight.)

Weights listed are approximate change from operating weight.

Hub odometer, miles or kilometers . . . . . . . . . . . . . . . .2 kg 5 lb

Disabled truck quick connects . . . . . . . . . . . . . . . . .13.5 kg 29.8 lb

Kim Hot Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 kg 35 lb

Fast fill fuel, Wiggins left-hand side . . . . . . . . . . . . . . .2 kg 5 lb

Fast oil change, Wiggins (engine) . . . . . . . . . . . . . . . . .7 kg 15 lb

Service center, Wiggins left-hand side . . . . . . . . . . . .36 kg 80 lb

Muffler, deck-mounted . . . . . . . . . . . . . . . . . . . . . . . .50 kg 110 lb

Fire extinguisher . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14 kg 30 lb

Body liners

–19 mm 0.75" floor, 9 mm 0.35" side, front and rear half of canopy (400 Brinell Steel) . . . . . . .8320 kg 18,340 lb

Source : Komatsu